41708 Half Cab

Winter 2025

We start the latest update on our Half Cab 41708 with some devastating news. As some of you may already have read in the railway press, at the beginning of October the Roundhouse site was the subject of a targeted attack by a criminal gang who stole all the locomotive’s pipework and brass and copper fittings.

Parts stolen during the break in included various cab and backhead fittings, injectors and driver’s brake valve. Thankfully, all the locomotive’s heavy components are at Tyseley Locomotive Works, where they have been under overhaul since 2022.

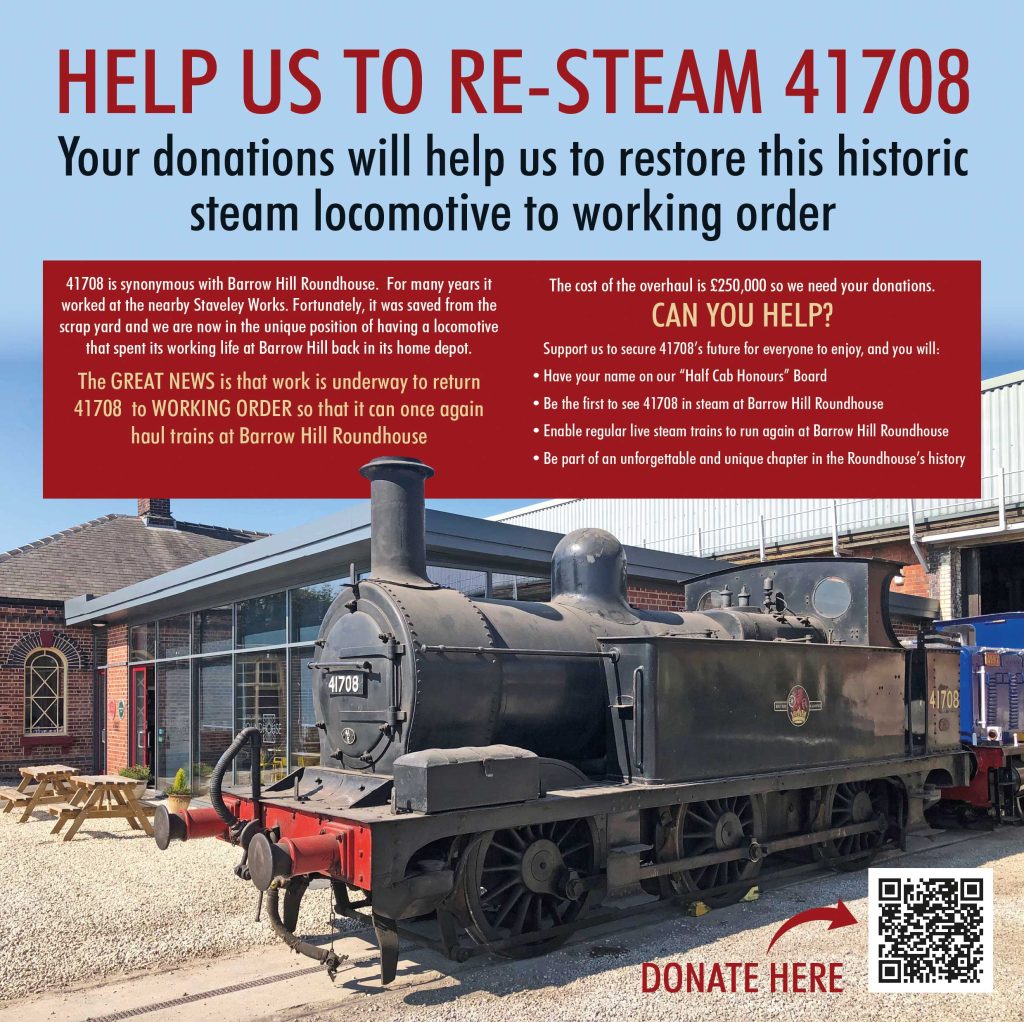

We had previously hoped that the locomotive would be launched back into steam in the summer of 2026, but we have had to concede that this is now an unachievable target. The loss of tens of thousands of pounds worth of original items has created an extra £125,000 black hole in our overhaul fund.

Derbyshire Police is investigating the theft but to date no parts have been recovered. Work to create the necessary patterns for casting and machining replacements could take some months or even years to complete.

In a quote provided to Trackside Magazine, Bob Burgess, BHESS Trustee said: “It is no understatement to say how devastated we are that the Half Cab has been vandalised in this manner. We are sure there will be many others who share our anguish. We can only appeal to people’s sense of generosity to support our historic little engine in its hour of need. Without that renewed support, our dream of running 41708 at its home shed and around the country is in serious jeopardy. We would be grateful for any contribution enthusiasts and well wishers can give to turn this desperately sad situation into something good”.

The easiest way to donate is to click on the button below which will take you to our Just Giving page. Please note that Just Giving will apply a discretionary fee to your donation to support their work but this can be reduced or removed entirely if you prefer not to.

If you are a UK tax payer you can also Gift Aid your donation through Just Giving which will add 25% to your donation at no cost to yourself.

Alternatively, if you would prefer to donate by bank transfer, debit/credit card or cheque – or have any other questions about making a donation – please email enquiries@barrowhill.org.

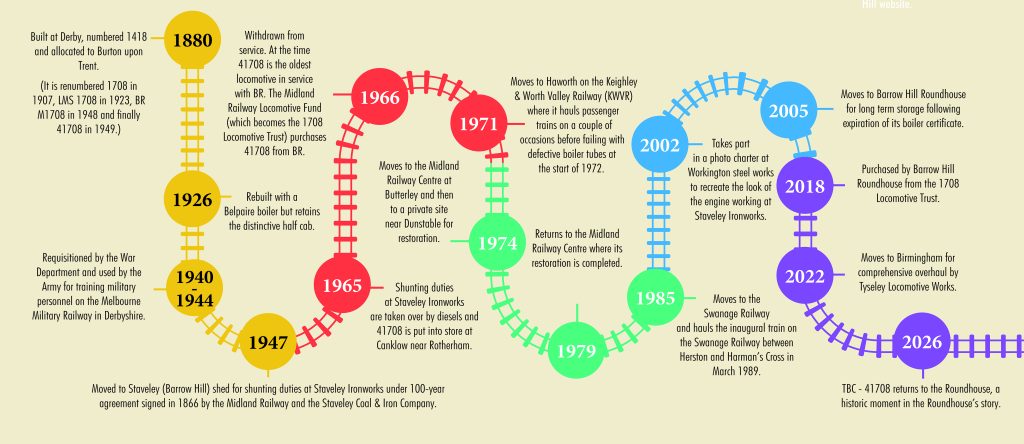

Significant Dates in the History of 41708

A Midland Railway Survivor

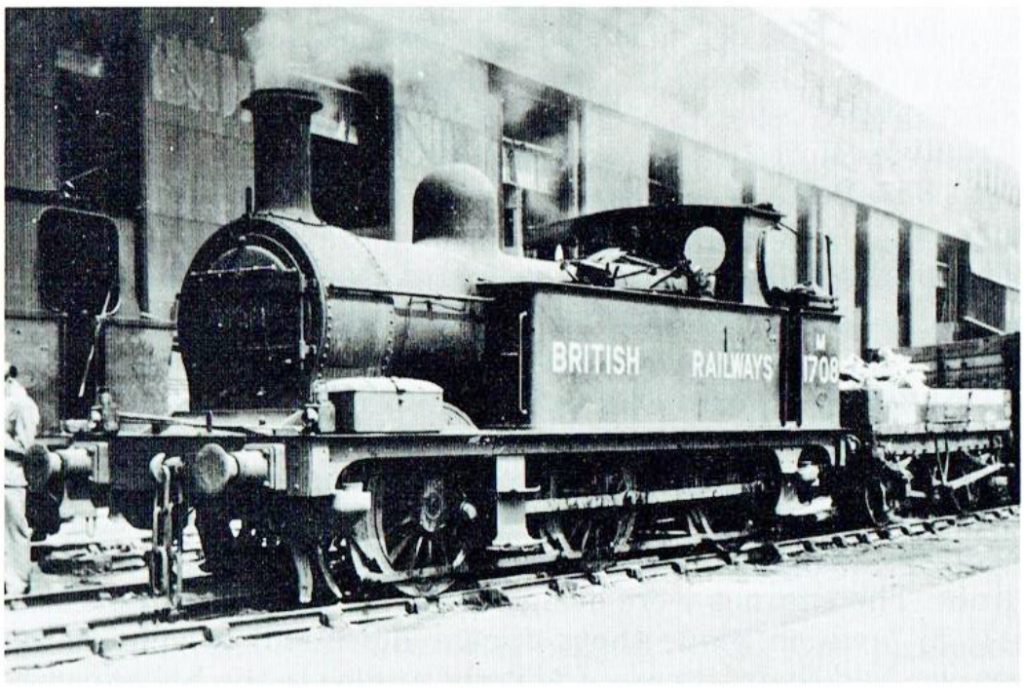

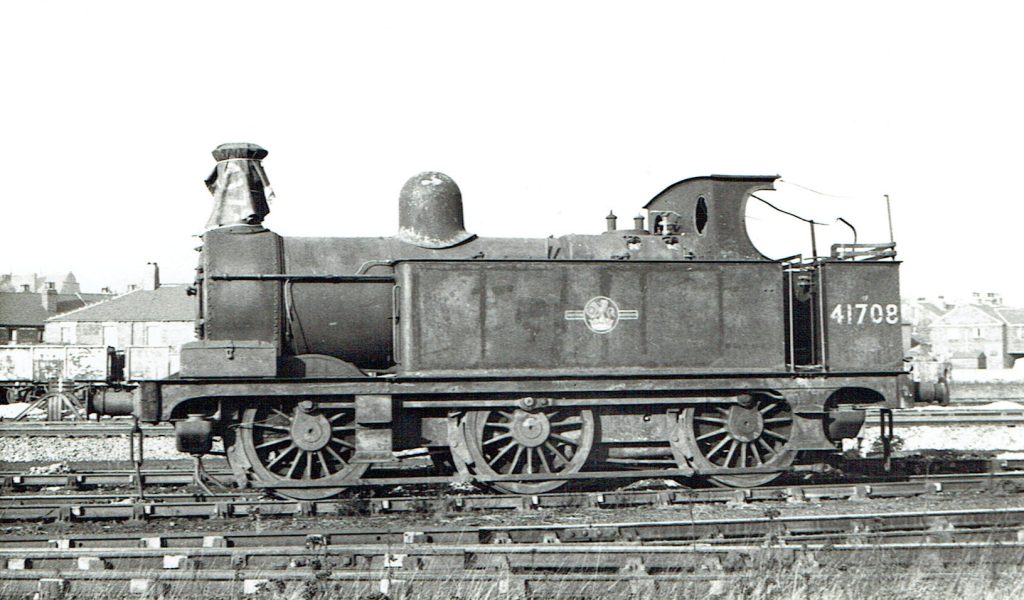

Midland Railway 1F 0-6-0T 41708 is the sole surviving example of the 185 members of the class to be built in Derby from 1878 onwards.

The 1F shunting engine was no railway superstar but, along with its home depot, Barrow Hill Roundhouse, it now provides a unique glimpse into the industrial backbone of the railways of Great Britain in the late 19th and 20th centuries.

This railway workhorse called several places home in its working life but the last 20 years or so were spent at Barrow Hill Roundhouse where it was serviced in between its shifts in the massive shunting yards of Staveley Ironworks.

In preservation the locomotive had a somewhat nomadic existence, as is often the case with heritage railway operations, being seen at galas and hauling trains on heritage railways up and down the country.

One of its appearances during this period was in 1998 when it attended the Barrow Hill Gala which celebrated the reopening of the Roundhouse as a museum and heritage railway centre following the long battle to save the building from demolition and vandalism.

In 2005 41708 returned to Barrow Hill, initially for long-term secure storage, but with the intention that it should one day become a permanent exhibit owned by the Roundhouse charity. That became a reality when the locomotive was purchased from the 1708 Locomotive Trust in October 2018.

Following its purchase detailed surveys were carried out to ascertain the condition of the locomotive and its boiler. These determined that a restoration to full working order was financially feasible. The locomotive is currently being overhauled at Tyseley Locomotive Works and its return to the Roundhouse is eagerly anticipated.

41708 is officially handed over to Barrow Hill Roundhouse. Photo credit: Barrow Hill Roundhouse

Overhaul Updates

Summer 2025

In June, several members of the Barrow Hill team – plus Graham Mimms of the 1708 Locomotive Trust, previous owners of the Half Cab – visited Tyseley to see for themselves how the restoration work is progressing on the locomotive.

It is a fair summary to say that there was some good news – and some not so good news!

First the good news. The work on the boiler is going well. The cracks in the barrel end have been repaired and the bottom corners of the backplate have had welded patch repairs; there is just a patch to be welded on the top corner. Work is also proceeding at pace on the motion. Having been taken apart and cleaned, everything is now going back together. Even the con rod, which as previously reported has at some point in the past been bent, just needs to be warmed up in order to straighten it. All six axle boxes have been inspected and cleaned. Some white metal repairs are required but nothing beyond what would normally be expected as wear and tear. New woollen pads are needed but these are a standard consumable item. The cylinders need de-scaling but are otherwise in good condition, as are the pistons, where the rings will be taken out for cleaning.

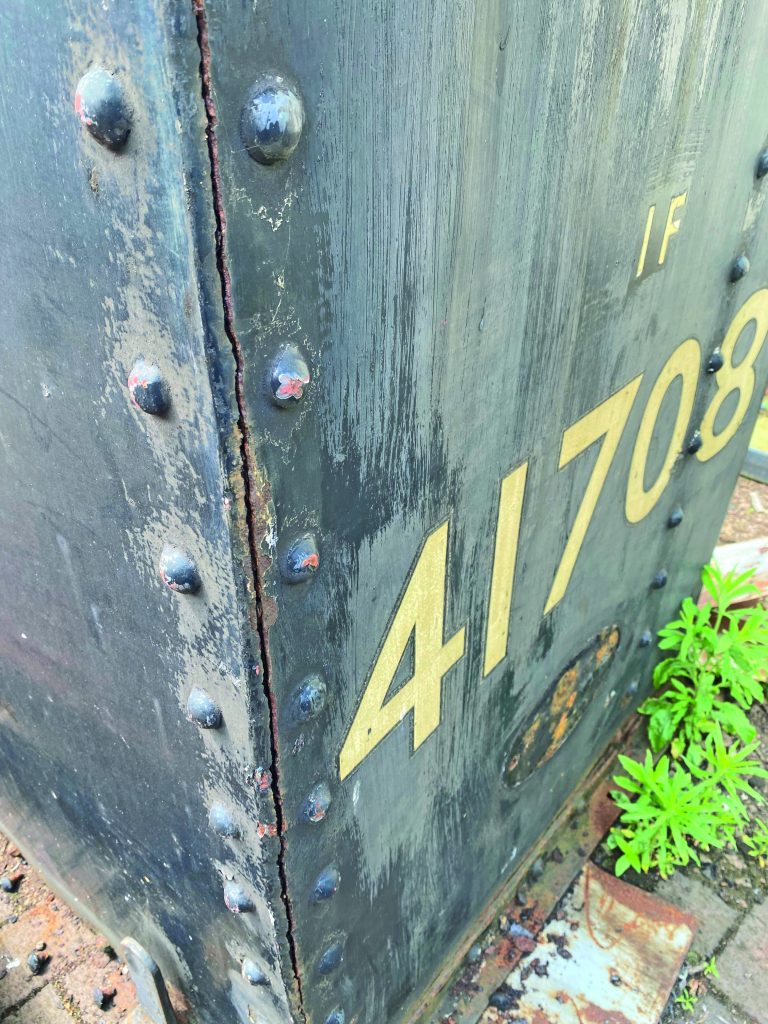

Now for the not so good news. The back end of the frames, footplate and bunker need a complete rebuild back to the buffer beam. As the ‘working end’ of the locomotive, over the years the combination of extreme heat, coal dust and water have taken their toll. Whilst not completely unexpected, this has added additional costs to the project as some parts are beyond economic repair and need to be re-built from scratch. However, in a light-hearted moment Alastair Meanley, who is leading the project at Tyseley, did point out that at least the cab steps are in relatively good condition and will be re-used.

Work has already started to replace the back end of the frames. New metal has been cut and is ready to be attached. Much of the back end metalwork is so severely corroded that it looks more like intricate lace work, laid out on the floor. We are looking at additional costs in the region of £20,000.

Whilst the Tyseley team has recovered the beading, lamp irons, handrails and bunker doors, the bunker itself is completely rotten with severe corrosion evident throughout. The only option is complete replacement at a cost of £5,000.

At the other end of the locomotive the smoke box also requires more work than originally expected; there are holes in the door and significant corrosion of the inner door ring, so these will both need to be replaced. The good news is that the wrapper is in good condition and can be reused. The cost of a new smoke box door and ring will be around £3,000.

Finishing on a positive note, now that the locomotive has been completely dismantled, the chances of finding any more costly issues are minimal – we do now know the full picture. The Tyseley team is also still confident that the overhaul will be completed in 2026.

And so on to the 41708 Appeal. As mentioned in the last Magazine, we now have a dedicated page on the Barrow Hill website for the locomotive, including links to our Just Giving page.

We also have a display in the Roundhouse to share 41708’s story with visitors, as well as banners and posters. We are delighted to have already raised several thousand pounds from generous donations – which will be increased thanks to Gift Aid – but there is still a long way to go!

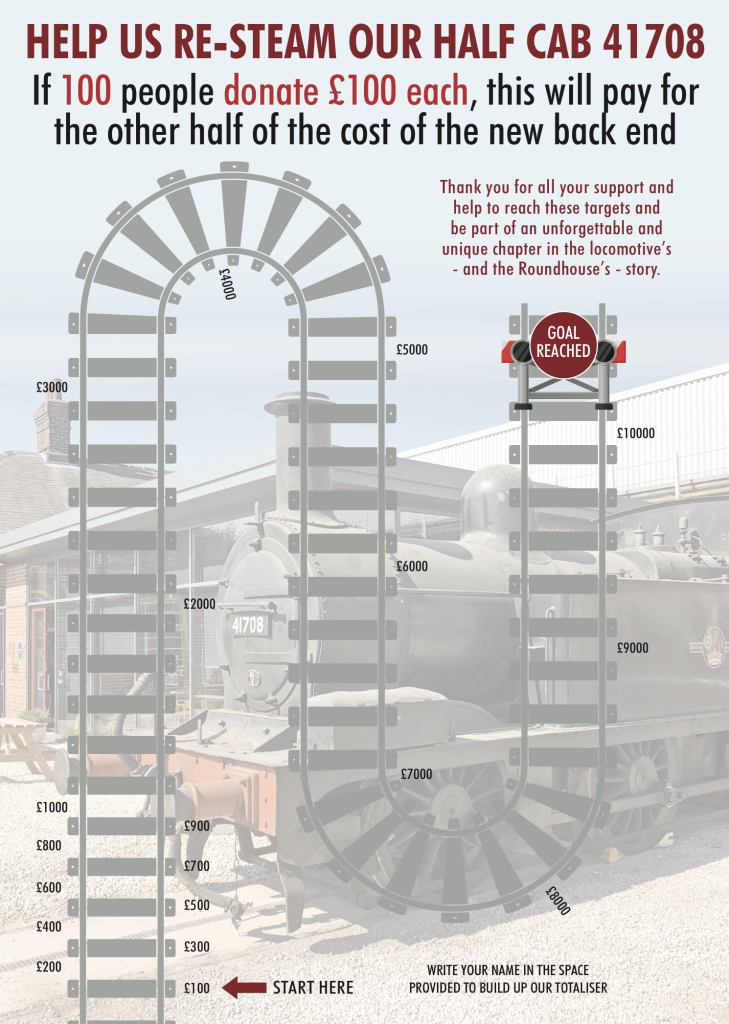

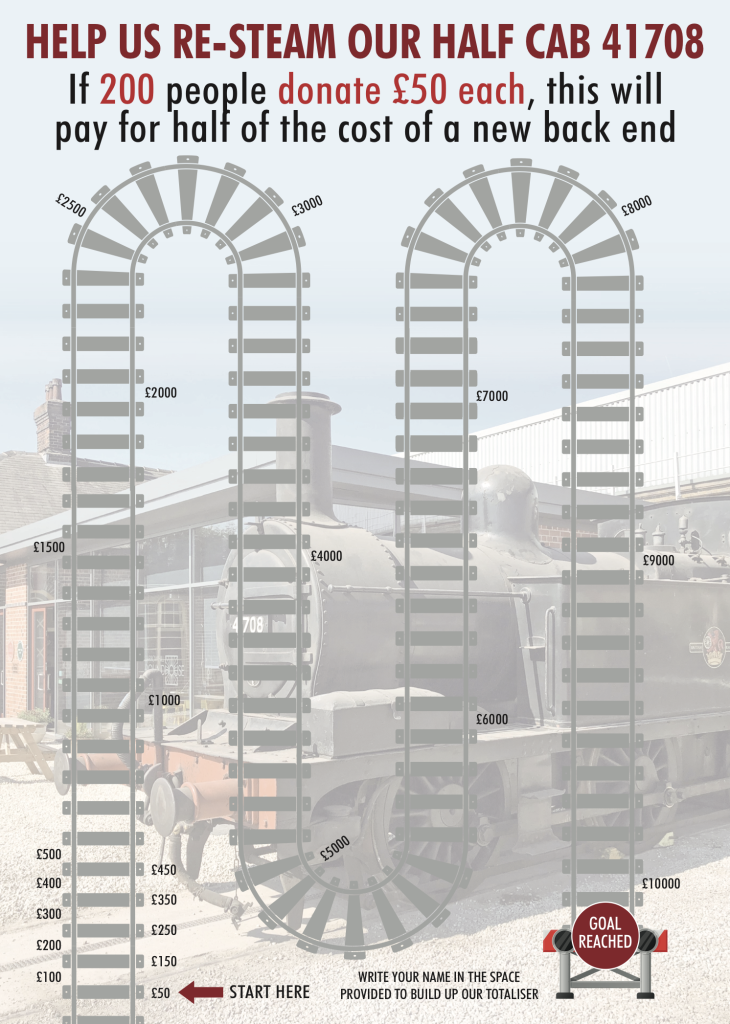

So that donors can really feel that they have made a difference, we have created four targets specifically aimed at helping us fund raise for the additional costs that have now been identified.

These are:

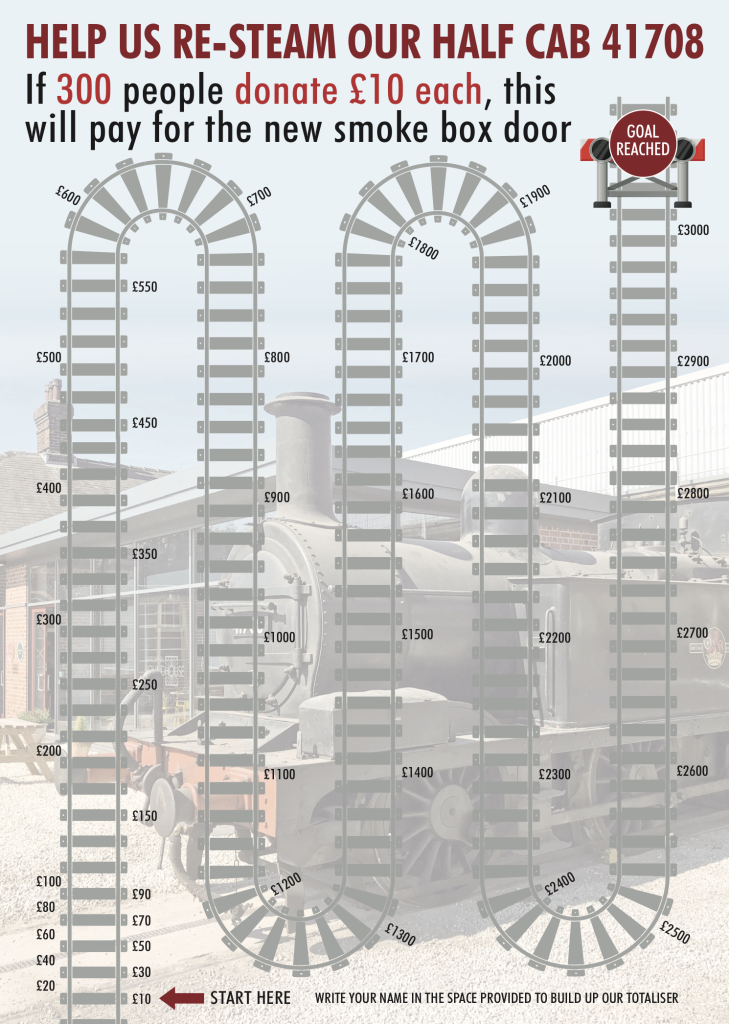

If 300 people donate £10 each, this will pay for the new smoke box door.

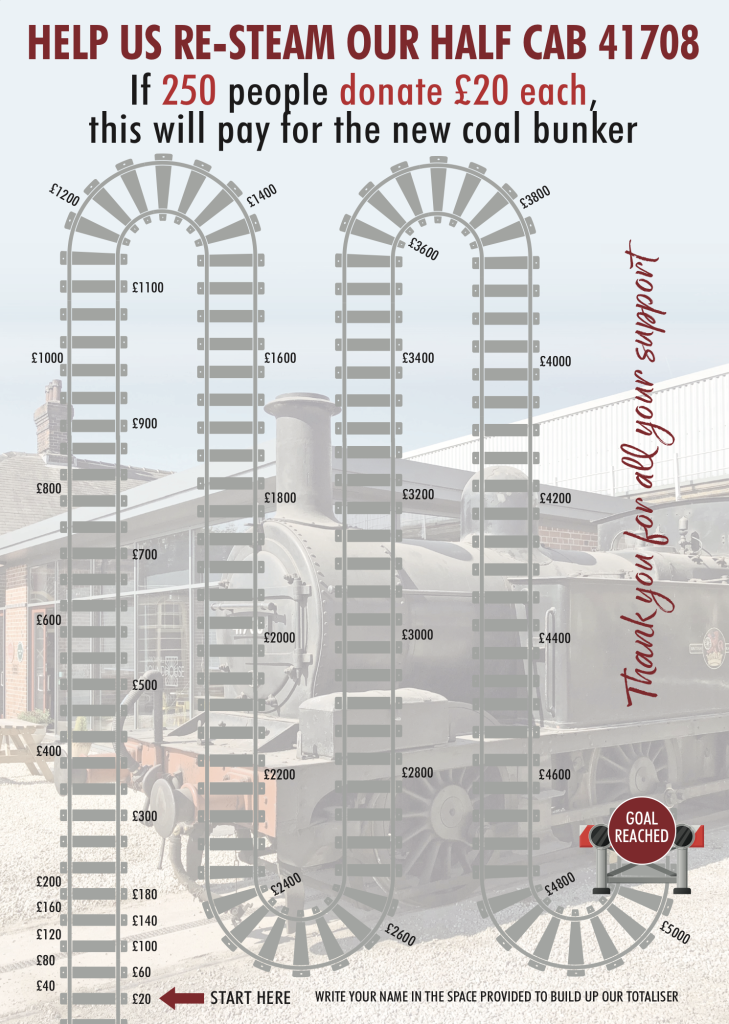

If 250 people donate £20 each, this will pay for a new bunker.

If 200 people donate £50 each, this will pay for half of the back end repairs.

If 100 people donate £100 each, this will pay for the other half of the back end repairs.

Anyone donating to one (or more) of these four targets will have their name written on the donation boards specially created for these appeals. Donations can either be made via the Just Giving page or by emailing me at alexa@barrowhill.org.uk.

I cannot wait to see the locomotive back in steam and I hope, with everyone’s help, we can make it happen. I know that there are many calls on people’s finances but if you can make a donation, however small, it would be hugely appreciated – thank you!

Summer 2024

Since the last report, progress has continued at a fair rate of knots, concentrating on the dismantling of the frames and lifting out of the wheelsets.

As a result, the engineers at Tyseley have been able to gain a much clearer understanding about the condition of our venerable locomotive, which, for those who do not know, started its long life in 1880 at Derby Works.

With the emphasis on the mechanical disassembly, this aspect is almost complete and there is some good news, and not so good news, which we will deal with first and get out of the way.

It was previously known that the bunker, which holds the locomotive’s coal supply, was not in the best of order and after closer examination we now know it needs completely renewing. Unfortunately, the corrosion damage done to the floor area is worse around the end frame sections which will also have to be renewed and further underneath into the drag box area. The drag box is the part of the frames that transfers all the force produced by the loco through the draw bar onto the train. The extra cost of repair is unknown at this stage. Further examination continues about rectification work in this important area of the locomotive, but now the locomotive is stripped so we can at least see the area and gauge the work required.

Conversely, news about the wheelsets is good – hooray! – with all axle boxes nowhere near repair limits and clearances looking fine, including the crank axle box which, according to Alastair Meanley from Tyseley, are all ‘like new.’ All the tyres are in good order as well, but Tyseley will ‘take a skim’ of each wheel (tyre turning) as the rebuild continues.

Barrow Hill stalwart Jeff White has done us proud by sourcing a local foundry who are casting a new blast pipe (which is located in the smokebox) for us. The old one is cracked and has come to the end of its life.

The volunteers back at the Roundhouse keep up the good work, continuing to refurbish, where possible, the ‘backhead’ fittings (parts located on the boiler around the cab area), which will help speed the rebuild at Tyseley. Still to go down to the Midlands, as and when required, are the side tanks and dome, all big items which require painting prior to their journey.

41708’s frames.

Photo: Mervyn Allcock

Two of 41708’s wheelsets with crank axle.

Photo: Mervyn Allcock

We have to remember that every part of the locomotive has be taken apart, tested and calibrated. This includes gauges, safety valves, steam injectors, vacuum ejector, motion lubricators, brake gear, axle box lubrication – the list goes on! Then they can be re-fitted back on the loco – a lengthy job.

The boiler repair work necessary, highlighted by the boiler inspector and Tyseley workshop boilersmith, indicated further welding/plating is required around the foundation ring. Extra plating is also required on the wrapper sides and around the firehole door. A new smokebox tube plate has been made and the boiler tubes are on order in readiness for when the boiler rebuild begins in earnest.

Interestingly, what came as a complete surprise was the sight of a bent con rod, which came to light as the engine motion was stripped. Fortunately, it appears no further damage has been done and the part will be closely examined, repaired and made good. No-one seems to know (or is owning up to!) when, or how, this misdemeanour happened.

All the firebars are being replaced with new ones and, whilst the ash pan is in fair condition, it will need some further fabrication work before re-fitting.

Attention will soon be given to the regulator valve, located at the highest point of the boiler in the dome. Then the main internal steam pipe will be fitted, which carries steam to the cylinders below.

Finally, closer examination tells us both buffer beams, after bearing the brunt of many shunts (some clearly not so smooth!) over the years, need straightening. The combination of part metal/timber construction is overdue for replacement. This will not be the ‘work of a moment’ but two Jarrah crossing timbers are being sourced to complete the task.

Spring 2024

On 8th March Mervyn Allcock and BHESS Trustee Bob Burgess visited Tyseley to view progress on our Half Cab 41708. The team at Tyseley are forging ahead with the full refurbishment as can be seen from these photos.

Photos: Bob Burgess

Summer 2023

A full NDT survey of the boiler has been carried out to determine the condition of the boiler. Photo 2 shows a general view of the NDT work and current condition of the boiler.

Ashdale Engineering have been appointed to carry out all inspections and approvals for the boiler using their engineer surveyor Bob Garnett. Bob has inspected the boiler and agreed the previous scope of repairs required. Following thorough NDT the boiler barrel is considered fit for further service. There is some wastage to the angle ring that attaches the front tubeplate to the front of the barrel. This will be removed for further NDT and some weld repairs. Photos 1 and 6 show all the rivets have been removed ready for the removal of the angle ring.

The lower sides of the firebox have been removed due to wastage and the new material is on site for drilling/machining and welding back into the firebox (photo 4 shows this work).

The lower part of the firebox throatplate has had the stays and foundation ring rivets removed and, once the boiler has been re-positioned, it will be cut off for renewal (photo 3 shows this work in progress).

Following NDT and ultrasonic testing of the firebox doorplate it was found that there was grooving up the end row of stays on either side. It has been agreed with the boiler inspector that a patch over both corners will be an acceptable repair and all copper stays have been removed from this area to facilitate this work. Photo 5 shows the firebox doorplate with the end rows of stays removed and the firehole door ring rivets removed due to wasted heads and to enable weld repairs to be carried out to cracking in the copper plate in this area.

The new front tubeplate will be of the fabricated type rather than pressed as this will save money on making flanging blocks and pressing, etc. This is quite common for this type of tubeplate nowadays and the steel profiles for the new front tubeplate and flange are on site. These will be drilled/machined and the flange welded to the plate during the coming weeks (photo 7 shows the new plate).

All boiler mountings studs have been removed from the firebox doorplate and the dome for renewal.

Photos: Alastair Meanley

Spring 2023

The Roundhouse’s resident Half Cab 41708 has been moved to Tyseley to undergo a thorough restoration to allow it to once again be steamed and work trains on the Springwell Branch.

The team at Tyseley, led by Alastair Meanley, is providing regular reports to the Trustees on progress. So far all the remaining fittings and pipework have been removed, cleaned up and put in safe storage. The smokebox rivets have been removed so the smokebox can be taken off from the front tubeplate for re-use. The dome cover has also been removed to allow access to remove the regulator valve and steam pipe. Finally the rivets from the tubeplate and angle ring to the barrel have been removed to recover the angle ring for re use on the new barrel.

The latest report from Tyseley relates to the boiler, where they have been cutting out rivets on the boiler barrel and tubeplate ready for removal. The boiler will then be moved into the workshop.

One of the remits of the Tyseley team is to re-use as many original parts as possible, as long as it is safe to do so of course. In any steam locomotive’s working life, life expired parts will be replaced, and this is the case with this current overhaul of 41708. However, the locomotive will still definitely be 41708 at the end of the restoration process!

Thank you to Alastair and the Tyseley team for keeping us updated and doing such a great job!

Photos: Alastair Meanley

Winter 2022

On 13th October 2022 our Half Cab 41708 started the next exciting chapter of its long life. The boiler was lifted off the Lowmac wagon on which it had been stored for several months while it was inspected and reunited with the underframe. The locomotive was then very gently moved onto a low loader by the Reed Freight team, a process which took most of the day to complete.

41708 then made stately progress through Barrow Hill village and on to the M1, its ultimate destination being Tyseley Locomotive Works in Birmingham where its restoration and overhaul will take place.

Photos: Mervyn Allcock

41708 – The Preservation Years – by Graham Mimms

41708 was never intended to be the locomotive preserved by the Midland Railway Locomotive Fund (MRLF). The original “Fund” comprised of a small group of Luton (Bedfordshire) train spotting friends who formed the basis of the original team of heritage railway volunteers.

In 1962 most were also members and working volunteers in the London Railway Preservation Society (LRPS) which had established a Luton-based collection of locomotives and rolling stock based at the National Cold Store sidings located at Skimpot on the former GN/LNER branch line midway between Luton (Bute Street) and Dunstable (North) stations.

Midland Railway Locomotive Fund

The founders of the Midland Railway Locomotive Fund (MRLF) started meeting regularly from circa 1965 and comprised supporters in early employment and those completing education. The core group met on Monday evenings. Other group members attended when their employment hours permitted. There were also others who attended meetings from time to time and helped with the funding projects.

It was originally intended to try and save an ex-MR / LMS 2P 4-4-0 locomotive but due to early scrapping and the lack of funding at the time there were only two types of former Midland Railway locomotives remaining in service within possible reach financially. To this end it was decided to target a Johnson 0-6-0 Half Cab Tank as there were still some in existence. 41712 was examined at Coens scrap yard at Kettering but, whilst this would have been ideal and possibly less expensive, the group did not have sufficient funds to acquire it at that time and it was scrapped.

Fund Raising

At every Monday evening meeting there was a weekly collection from attendees. Fund raising was enhanced considerably by establishing a “Football Lottery” Club with worthy prizes which raised regular and growing revenue for the MRLF. Other enterprises for raising funds included making professional quality picture frames containing locomotive illustrations and the sale of railway merchandise at model railway exhibitions and traction engine rallies and similar events in the Beds, Bucks and Herts areas.

The Association of Railway Preservation Societies (ARPS)

At the time the MRLF was formed the ARPS had not been long established. It collectively represented and promoted developing railway preservation groups in the UK and was headed up by Captain Peter Manisty. The MRLF sought advice from the ARPS on purchasing a suitable locomotive from British Railways located in the Staveley and Barrow Hill areas east of Chesterfield.

Locomotive Selection

A former BR locomotive fitter undertook preliminary surveys of each of the former Midland Railway Class 1F locomotives, some of which still retained their original “Half Cabs”. All the remaining locomotives had been fitted with Belpair boilers. Located along with the 1F’s were some Class 0F 0-4-4T designed by R. M. Deeley that were introduced in 1907.

After the inspections it was decided that the locomotive deemed to be in the best condition was 41708 and plans were prepared to see if the Fund could raise the amount needed to acquire it. At the time BR were asking unrealistic, well above scrap value prices to sell locomotives for preservation. BR was committed to a modernisation plan which did not sit well with steam locomotives so discouragement by price was the order of the day!

Several other groups were in the same position and it was agreed with Pster Mainsty that the ARPS would negotiate a deal with British Railways for the purchase of three locomotives of National Historic Interest of which 41708 would be one. In late 1966 BR agreed to the ARPS proposal and a price of £875 was required for the MRLF to acquire 41708.

The Move to Haworth

There was just about enough in the bank and with loans from members the purchase was concluded and the locomotive was moved in March 1967 to the then embryo Keighley & Worth Valley Railway (K&WVR), which was the closest heritage railway and the least costly to move to. 1Fs had previously operated on this line line so if 41708 could be made operational again it would be very fitting indeed.

In early 1967 representatives of the MRLF drove from Luton to Sheaf House (BR Eastern Regional Offices) at Sheffield Midland Station and handed over the all-important MRLF cheque to officially take ownership of the locomotive. They then drove to Canklow locomotive shed where the batch of former MR locomotives were in store. They examined and prepared an itemised schedule of all 41708’s component parts and their condition. This was followed up by a second visit to Rotherham Masborough station where 41708 and other locomotives had been moved to. Some parts had gone missing in the move but thanks to the original visit 41708 was made complete as paid for.

Hot Box

41708 was towed from Rotherham Masborough towards Keighley station but en route a “hot box” was detected, and the engine was dropped off at Leeds Holbeck Locomotive Depot (55A). Once at the shed the best of British Railways and its staff went into play and 41708 was lifted on to sleepers in the shed yard where the wheels and axle boxes were removed and sent to Neville Hill shed in Leeds for turning and repair. An excellent job was undertaken and the parts refitted after which the locomotive was successfully delivered to Keighley and the care of the K&WVR. The MRLF was never billed for the work at Leeds!

At Keighley the K&WVR volunteers took the locomotive to Howarth and set about examining the locomotive with the view to a steaming in the near future. It was agreed by the boiler inspector that after some preparatory work, which was undertaken during 1968, he would approve a test run. This took place in early 1969. For operational insurance 41708 was double-headed with the K&WVR’s Ivatt 2-6-2T number 41241. A postcard was made of the event.

Because of concerns of leaking tubes developing, 41708 remained at Oxenhope after completing the first run while 41241 continued with its roster. There was only a little coal left in 41708’s bunker and to maintain the fire to facilitate steam to return to Haworth at the end of passenger operations it was necessary to hunt for wood. Eventually the locomotive was able to steam carefully back to Haworth.

Formation of the 1708 Trust

The ARPS advised that the MRLF should be formally established as an appropriately constituted preservation organisation such as a charity or a company limited by guarantee. This led to the formation of the 1708 Locomotive Preservation Trust (1708 Trust) in 1971.

Midland Railway Trust

In 1971 the 1708 Trust received a proposal from the Midland Railway Trust at Butterley to take the locomotive there where they would seek to return it into working order to work on their line. This was discussed with the K&WVR who agreed that because of pressures on their own resources this would probably be the best way forward. Accordingly, plans were set in motion to move the locomotive from Howarth to Butterley by low loader. The move was duly arranged in the winter of 1971.

Remedial work was undertaken and the locomotive was put on display. It was here that the replica “full cab” was manufactured, which was subsequently used when masquerading as other members of the class for photographic charters and in bad weather for the protection of the crews.

In 1973 the 1708 Trust established a base at the Blue Circle Cement Works at Houghton Regis near Luton. Here the Trust rented sidings where the manufacturing facility had previously ceased operating in 1971. It was still extensively used for rail borne cement traffic for distribution via a connection to the Luton to Dunstable branch of British Railways. The 1708 Trust had use of the still extensive internal rail network at weekends when there were no railway activities taking place. It was therefore decided to move 41708 to Houghton Regis to be kept in a secure compound which the 1708 Trust members had constructed with workshop facilities.

It was agreed with the Midland Railway Trust who, like the K&WVR, were under pressure to maintain their own collection, that 41708 would move further south where the 1708 Trust members could be more hands-on. Subsequently 41708 moved by road to Houghton Regis via the M1.

On arrival at the compound at Houghton Regis 41708 became the main focus of working party maintenance activity. An early job was to remove 41708’s cab and side tanks so the boiler could be examined. A crane was employed to undertake this work. This work involved removal of the asbestos lagging which had to be carefully replaced.

In 1980/1981 the 1708 Trust was informed by Blue Circle that the site had to be vacated for redevelopment. 41708 returned to the Midland Railway Trust where further renovation work was undertaken.

Swanage Railway

In 1983/1984 41708 was transferred to the Swanage Railway under an agreement that it would be restored into full working order. This process was overseen by the then Operations manager Martyn Ashworth under whose supervision 41708 became the first ex-BR steam locomotive to operate on the line.

For several years 41708 was an important and valuable asset in the development of the Swanage Railway. Eventually this success led to the need to operate heavier and more frequent trains with larger locomotives so 41708 was once again seeking a suitable new home. This is how 41708 became permanently based at Barrow Hill, considered by the 1708 Trust as the most suitable place as the locomotive had previously spent much of its former BR working life based at this shed.

Other Heritage Railway Visits

2000 – Great Central Railway (where 41708 sustained a hot box which was repaired)

2001 – Great Central Railway (North)

2002 – Goole Docks and Workington British Steel

2003 – Avon Valley Railway, Bristol Harbour Railway, Cholsey & Wallingford Railway, Llangollen Railway